Block coil dipoles are appealing for their simplicity in the body of a magnet, but less so in the ends of the blocks that must clear the beam tube. The required bending of the conductor typically is in the hard direction of the broad cable, and therefore must be very gradual, to avoid conductor degradation from excessive strain; the end regions become undesirably long.

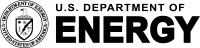

The overpass/underpass or cloverleaf end geometry is designed to overcome the above-mentioned shortcomings. The conductor clears the bore tube at the ends by replacing the hard-way bends with a gentle twist in a 270° ramped turn (see below). The end regions extend relatively little beyond the straight legs. The strain on the cable in the ends remains low if the conductor is allowed to tilt to minimize its strain.

Overpass/Underpass (Cloverleaf) design for magnet ends.

An easy way to understand this concept (the path of the cable) is to imagine the cable as tracing the path of an automobile reversing direction via an overpass/underpass bridge. The cable (or automobile) clears the beam (traffic) via the overpass/underpass, returning to its original highway with reversed direction of travel, as desired. The cable (or automobile) clears the beam (traffic) via the overpass/underpass, returning to its original highway with reversed direction of travel, as desired. The coil ends clear the beam tube without a hard-way bend.

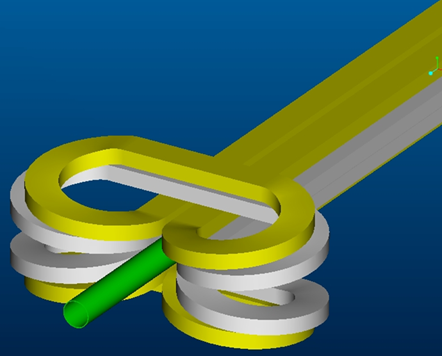

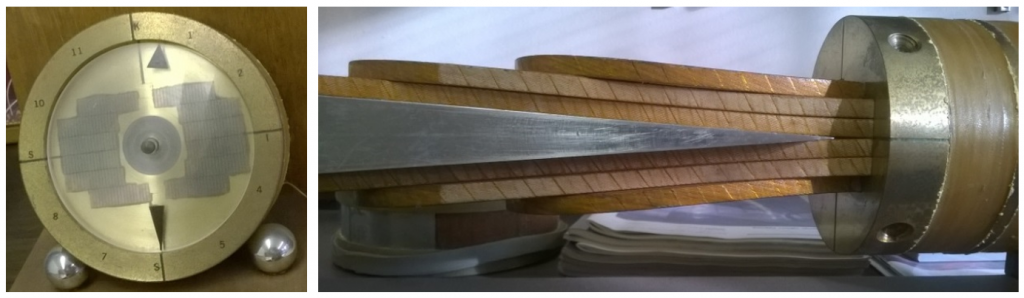

Photos of an early block coil design by Sampson at BNL are shown below, with the coil cross-section shown on the left, and the conventional magnet ends, with Rutherford cable gently lifted, shown on the right. Since then, several more Nb3Sn block coil designs with lifted ends have been designed, and a few built: (a) a 13.8 T, 36 mm aperture dipole (named HD2) at Lawrence Berkeley National Laboratory (LBNL), (b) a 13 T, 100 mm aperture dipole (FRESCA2) at CERN, and (c) a high field block coil magnet at Texas A&M and they all are subjected to the same issues.

Nb3Sn block coil dipole with cross-section (left) and lifted ends (right).

The proposed overpass/underpass design replaces the hard-way bend with a gentle twist. Moreover, unlike in dog-bone ends (another design which was used in several Nb3Sn react & wind R&D magnets built for the Superconducting Super Collider or SSC, see below), no reverse curvature is involved. The cable traverse involves a twist or tilt, as typical on an overpass/underpass of a high-speed expressway.

Nb3Sn React & Wind dog-bone ends for R&D dipoles for the SSC Program (Palmer, et al)

The overpass/underpass geometry offers major benefits for magnets built with built brittle conductors such as Nb3Sn or High Temperature Superconductors (HTS), and with NbTi as well.

The overpass/underpass design is being considered at CERN (referred to as the cloverleaf there) for the 20 T HTS dipole program. HTS coils based on this designs have been built and tested both at BNL and at CERN.

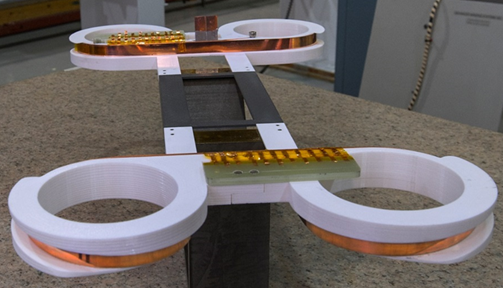

Overpass/Underpass HTS coil built and tested at BNL as a part of an SBIR with e2p.

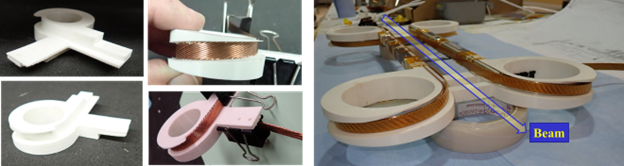

Overpass/Underpass winding with NbTi Rutherford cable as a part of an STTR with the Particle Beam Lasers, Inc. (PBL).

Overpass/Underpass winding with Nb3Sn Rutherford cable as a part of an STTR with the Particle Beam Lasers, Inc. (PBL).

Mock-up insertion test of a Nb3Sn overpass/underpass coil in the BNL common coil dipole DCC017 as a part of an STTR with PBL.