The dipole DCC017 represents a new design and philosophy that not only successfully demonstrated several design features for the first time but also facilitates a new way of doing low-cost, fast turn-around magnet R&D that was not possible before. A few of many new features:

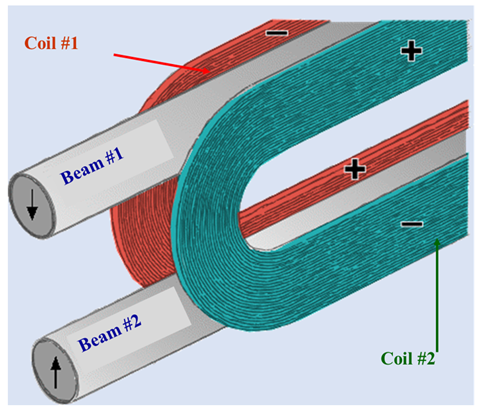

- Common coil design, primarily based on simple coil geometry

- Conductor friendly geometry allowing “React & Wind” technology

- Offering a new low-cast, fast-turn around magnet R&D approach

The initial vision was presented in an internal note and in a paper in 1996. It evolved over time till the magnet was built and tested in 2006. Successful demonstration of an out of box magnet like DCC017 is a testimony to the excellent team of technicians, engineers, and scientists, supported by the management.

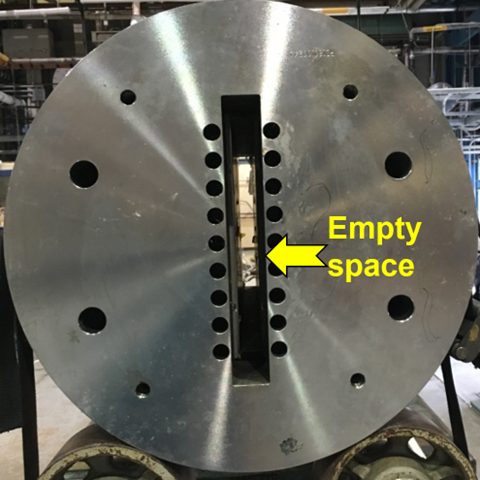

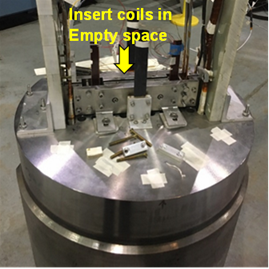

The common coil design was inspired by the potential of High Temperature Superconductors (HTS) in accelerator magnets. It is a modular design primarily consisting of simple racetrack coils. A new module can be added or replaced to carry out a proof-of-principle demonstration of a new idea or technology. This is an alternative to building a whole new magnet which is order of more magnitude more expensive and takes several years to build and test. The picture below shows how one or a set of coils could be inserted to become part of the magnet without requiring disassembly and reassembly of DCC017.

Providing a clear open space in the design required a large unsupported vertical coil module. There were many concerns for such a design, such as the coil module buckling, etc. The concept relies on the Lorentz forces pushing the main and insert coils towards the structure.

DCC017 reached its computed short sample in 2006. Demonstration and effective commissioning of DCC017 as a low-cost, rapid turn-around facility was carried out under an SBIR with Particle Beam Lasers, Inc. (PBL) in 2017, when a record 8.7 Tesla HTS/LTS hybrid dipole field was also achieved. This led to the funding of several other proposals from a variety of sources.

HTS insert coil test under US Magnet Development Program (MDP) in 2020 demonstrated a vast potential of this unique magnet when four samples/coils were tested in one go. That test not only proved critical for demonstrating a new fusion cable, but also created a new record of 12.3 Tesla HTS/LTS hybrid dipole field.

DCC017 vision is now operational with more opportunities getting thought. A large open space for in-field integration of the insert coils or samples without disassembling the magnet facilitates:

- High risk, high reward innovative magnet R&D program at a low cost, with insert coil becoming an inherent part of the magnet

- Systematic magnet R&D program because of low-cost and rapid-turn-around of each test

- Unique test bed for high current cable in straight and bent configuration

- A vehicle for in-field testing of cable and insert coil at a variable temperature

- Testing of two test samples (cables or coils) in identical conditions in two apertures

See also:

- New Approach and Test Facility for High Field Magnet R&D (Paper)

- Unique Dipole for Low-cost, Rapid-turn-around Program

As such DCC017 is a successful demonstration of “react & wind” Nb3Sn technology which makes a large industrial production of high field magnets more reliable and viable. In fact, “react & wind” coils were also built with Bi2212 Rutherford cable as well ReBCO cable as insert coils to DCC017.

Another important demonstration was allowing large deflection of individual magnet coils as a unit without causing internal strain. This reduces the volume and cost of expensive support structure.