Common Coil Test Facility (CCTF) at BNL, based on a unique common coil dipole with a large opening, represents a new design and philosophy that facilitates a new way of doing low-cost, fast turn-around magnet R&D that was not possible before. It is currently being used by the High Energy Physics (HEP) and fusion community to test new cables and magnet concepts.

The initial common coil vision was presented in an internal note and in a paper in 1996. It evolved over time till a common coil dipole DCC017 (see above with a large opening) was built and tested in 2006. The magnet as a facility was demonstrated in 2016 when an HTS/LTS hybrid magnet design was demonstrated. This led to the funding of several other proposals from a variety of sources.

- Slide deck for more information on the Common Coil Test Facility at BNL

- Common Coil Design Explained

- The DCC017 Story

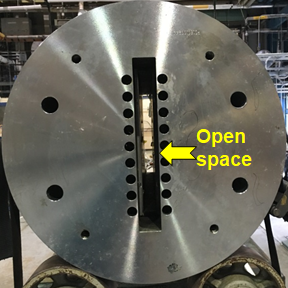

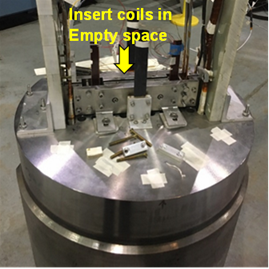

Common coil design is a modular design primarily consisting of simple racetrack coils. A new module can be added or replaced to carry out a proof-of-principle demonstration of a new idea or technology. DCC017 was designed such that a new module can be inserted without opening or disassembling the magnet. This is an alternative to building a whole new magnet which is order of more magnitude more expensive and takes several years to build and test. The picture below shows how one or a set of coils could be inserted to become part of the magnet without requiring disassembly and reassembly of DCC017.

Providing a clear open space in the design required a large unsupported vertical coil module. There were many concerns for such a design, such as the coil module buckling, etc. The concept relies on the Lorentz forces pushing the main and insert coils towards the structure.

The common coil test facility vision is now operational and being used by a variety of users, many were not even imagined in the beginning. A large open space for in-field integration of the insert coils or samples without disassembling the magnet facilitates:

- High risk, high reward innovative magnet R&D program at a low cost, with insert coil becoming an inherent part of the magnet

- Systematic magnet R&D program because of low-cost and rapid-turn-around of each test

- Unique test bed for high current cable in straight and bent configuration

- A vehicle for in-field testing of cable and insert coil at a variable temperature

- Testing of two test samples (cables or coils) in identical conditions in two apertures

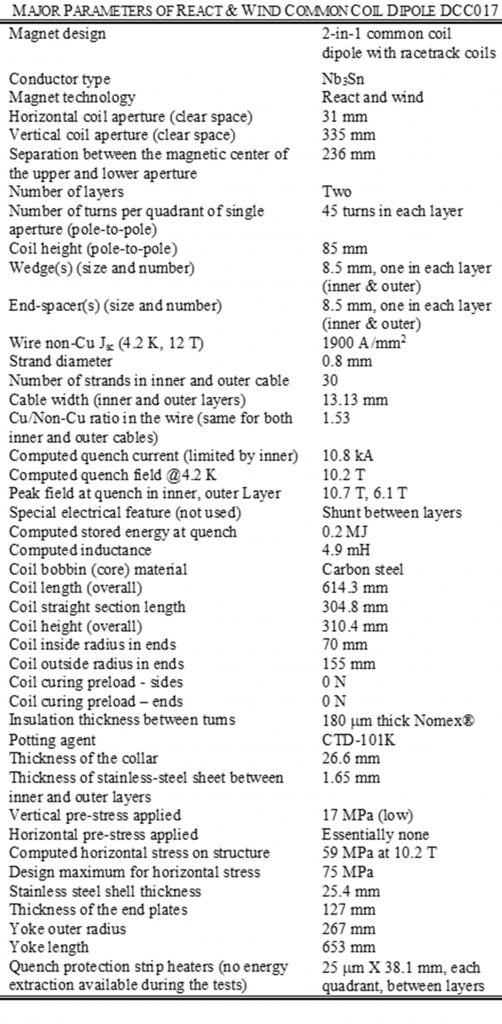

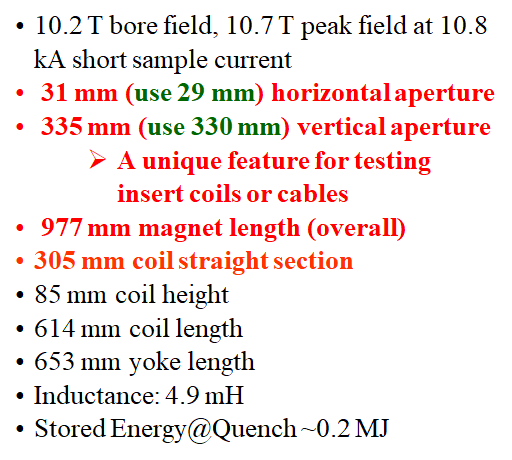

Key Parameters:

See also:

- New Approach and Test Facility for High Field Magnet R&D (Paper)

- Unique Dipole for Low-cost, Rapid-turn-around Program